In part one of this series on building Academy's M1A1 Abrams the basic hull was assembled, motorization holes filled, and a non skid texture was added to the upper surfaces. In part two I will go over the details and fixes for the rear panel and the suspension which consists of the road wheels, idlers, and main drive sprockets.

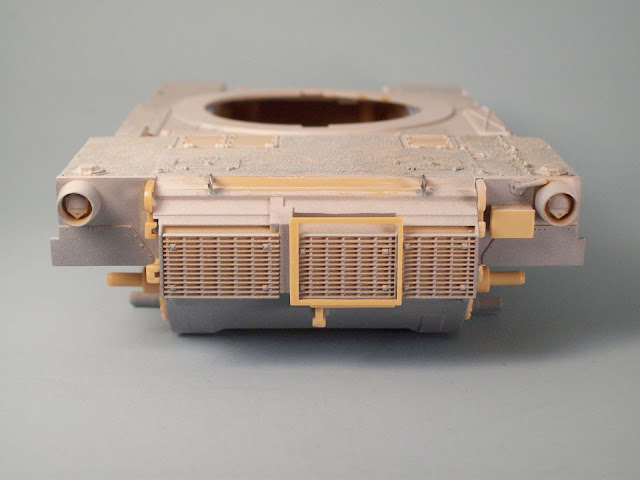

The photo above shows an overview of the rear panel. Everything here was assembled per the instruction sheet except for the addition of two missing lift rings. These can be seen directly over the main exhaust visible by their silvery color. In order to produce these I bent a piece of hollow core solder to shape then flattened it with a hobby knife. They were then glued on with CA and blended in with tiny amounts of Gunze Mr. Surfacer 1000. The below photo shows them in greater detail. They may not be entirely the correct shape but since I am a fan of the TLAR (That Looks About Right) method they are good enough for me.

A shot of the rear panel from head on shows all four hinges which are separate pieces in the kit. On a full scale M1A1 these hinges are attached to the vents which are designed to swing open for maintenance. The set on the left I think I may have installed upside down but I'm not entirely sure. If they are there is no easy way to fix it with the way they are glued on. The small box on the right hand side is the TI (Tactical Interface)

phone used to communicate with other tanks commanders in the field and this is one of the only Abrams I have seen recently to include one which is a small plus on this kit's behalf.

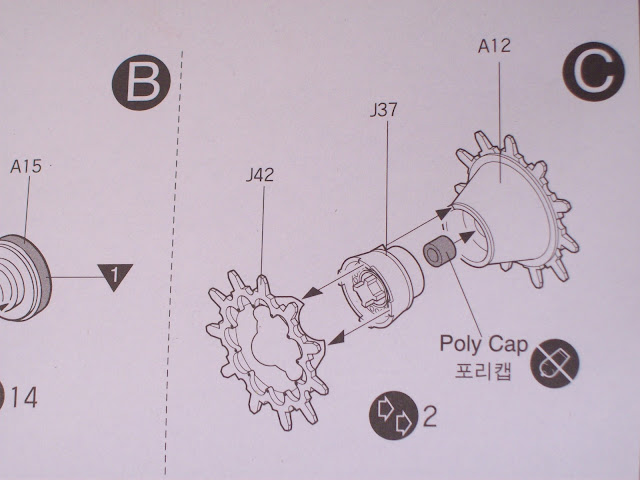

These two photos show the kits sprockets. As you can see from the instruction sheet snippet, they are a four piece affair that break down in such a way that there a plenty of unsightly gaps in areas that are nigh impossible to reach with sandpaper to properly smooth them out. After somewhere in the neighborhood of 4+ hours of work with Bondo putty, gap filling CA glue, and Mr. Surfacer 500 I got them to a point where they were "acceptable". I may be able to do a tiny bit more to smooth out some of the gaps but I don't think it's going to get much better than this.

Here are all fourteen road wheels, two idlers, and two sprockets together with the return rollers installed completing the suspension work. Each wheel consisted of two pieces with a vinyl grommet between them and each had three ejector pin marks on the inner surface along with a mold line around the circumference which made for a very fun two days getting them all prepped and assembled. Now that I think of it with the side skirts and tracks on you probably won't be able to even see any of this work, but that's just the kind of anal builder I am.

In part III of the W.I.P series on Academy's M1A1 I will start in on the DML mine plow kit to ensure it fits properly before moving on to the upper front hull details such as the drivers area and headlights. With the suspension now out of the way the rest of the basic assembly procedures should be a breeze!

No comments:

Post a Comment